How do Coordinating Heat Pump Installations With Plumbing Systems in Modern Homes?

Heat pump projects often feel like a pure HVAC upgrade, yet many installations touch plumbing more than homeowners expect. That is especially true when the plan includes a hydronic air handler, a heat pump water heater, a desuperheater for water preheating, or any setup where condensate and drainage routes matter. Even an air-to-air heat pump can require careful water management, since condensate lines, traps, and termination points must be placed correctly to avoid leaks, odors, and clogs. Coordinating with plumbing systems early helps prevent rework, keeps walls from being opened twice, and ensures equipment performs as intended. The goal is to treat the heat pump as part of a whole-home mechanical network rather than a standalone unit. When HVAC and plumbing trades align on layout, electrical needs, and drainage paths, the installation moves faster, and the final system runs more reliably. Clear planning also protects finishes and reduces the chance of small oversights that become big service calls.

Key Coordination Steps

- Mapping Water Lines, Drains, and Mechanical Space Before Equipment Arrives

The most practical way to coordinate a heat pump with plumbing is to start with a map of what already exists behind walls and under floors. Water supply lines, shutoff locations, drain stacks, cleanouts, and vent paths all influence where equipment can go and how easy it will be to service later. If the heat pump includes a heat pump water heater, placement affects hot water delivery times, condensate disposal, and noise transfer to living areas. Even if the project is only space conditioning, installers still need a plan for condensate routing, especially in humid climates or in basements where gravity drainage is limited. A condensate pump may be required, and that choice ties into plumbing decisions about discharge location and backflow prevention. During planning, it helps to confirm which walls are available for line sets, where penetrations can occur without hitting pipes, and whether existing plumbing can handle additional drainage. Many contractors coordinate from a Quincy office where scheduling and rough-in checks can be managed before crews arrive, reducing surprises on install day. The earlier the mechanical space is evaluated, the fewer last-minute compromises affect performance.

- Condensate Management and Drainage Details That Prevent Callbacks

Condensate is one of the most common overlap points between plumbing and heat pump work. Air-source heat pumps remove moisture during cooling, and in heating mode, certain configurations can also produce water that requires a defined path. The condensate line should have a proper slope, an appropriate trap when required, and a termination point that does not risk freezing, staining, or nuisance dripping near walkways. In many homes, the safest termination is connected to an approved drain with an air gap or an indirect connection, but this must follow local code and may require a plumber’s input. If the drain is connected incorrectly, odors can travel back toward the air handler, or the drain can clog and overflow into finished spaces. For attic installations, secondary drain pans and overflow switches reduce risk, but they work only when installed and tested. Another detail is material choice: some lines need insulation to prevent sweating, and others need protection from UV exposure if routed outdoors. Heat pump water heaters also produce condensate, often more than homeowners expect, so routing it to a floor drain or a properly trapped standpipe can help prevent dampness and mold growth. Good drainage planning makes the whole project feel clean and intentional.

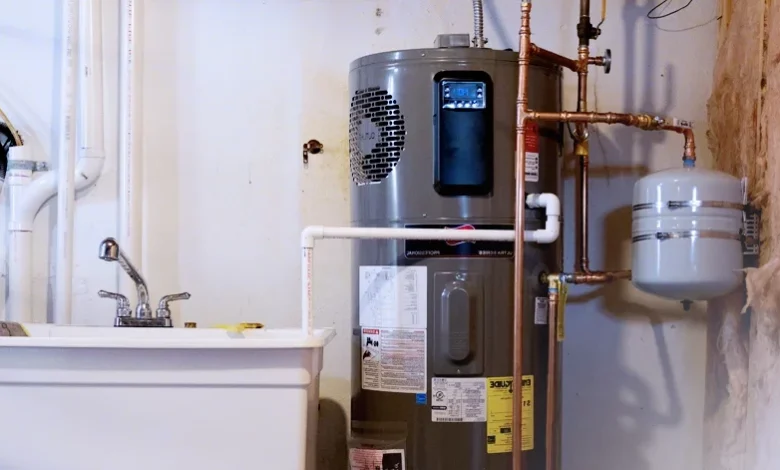

- Domestic Hot Water Integration and Piping Impacts

When a heat pump intersects with domestic hot water, plumbing coordination becomes even more important. A heat pump water heater changes the airflow and temperature around it, which can affect nearby pipes and valves. For example, placing the unit in a small closet with insufficient air volume can reduce efficiency and increase runtime, while placing it in a garage might require freeze protection for nearby lines. Piping layout matters too. If the home has long pipe runs, adding a recirculation line or a demand recirculation pump can improve comfort, but it must be sized and valved correctly to avoid constant energy use or unwanted mixing. Some heat pump systems offer water preheating, which can reduce the water heater load, but the plumbing arrangement must support safe temperatures and proper controls. Mixing valves can help manage scald risk, especially if storage temperatures are raised for hygiene or performance reasons. During coordination, it also helps to confirm the quality of pipe insulation, since heat pumps often aim to reduce overall energy use, and uninsulated hot water lines can undermine that goal. By aligning heat pump choices with piping improvements, the project can improve both comfort and operating cost without creating confusing service layouts.

Aligning Plumbing and Heat Pump Work for Fewer Problems Later

Coordinating heat pump installations with plumbing systems is less about adding complexity and more about preventing small oversights that lead to water damage, odors, or repeated service visits. A heat pump interacts with the home through drainage paths, mechanical space constraints, and sometimes through domestic hot water equipment, so early mapping of pipes and drains saves time and protects finishes. Condensate planning is a core step, since proper slope, termination, and safety protections reduce the risk of leaks in basements, attics, and finished areas. When domestic hot water is part of the project, thoughtful piping layout and temperature management can improve comfort while supporting energy goals. Sequencing trades, permits, and inspections keeps the job moving and prevents rework, especially when multiple crews need access to the same spaces. Finally, joint testing ensures the system performs as intended under real conditions, not just on paper. With careful coordination, homeowners get reliable comfort, cleaner mechanical rooms, and a project that feels organized from start to finish.